Facade Composite Panel

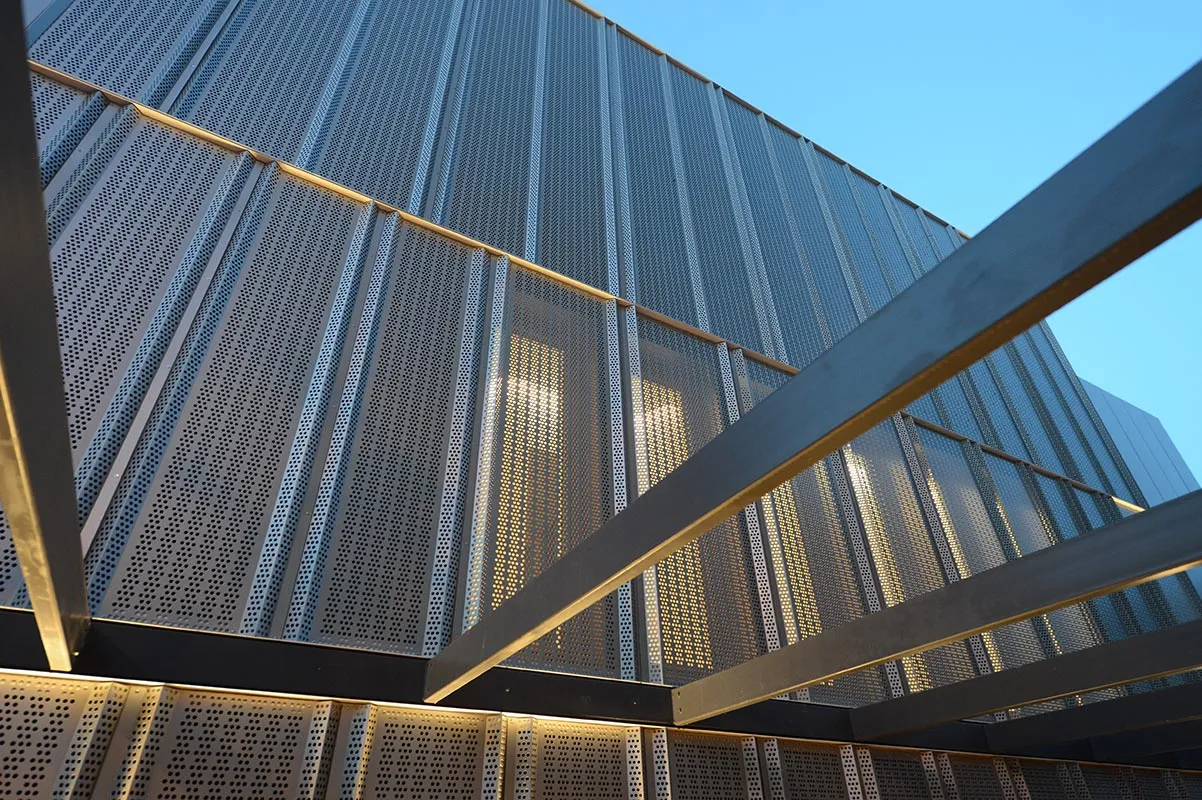

At Vision Art Aluminum, we offer top-of-the-line composite panels designed to meet the highest standards in modern construction. Our panels combine lightweight materials with exceptional strength, making them perfect for exterior cladding, signage, and architectural facades.

Manufactured using the latest technology, they deliver both durability and aesthetic appeal. With a core composed of polyethylene or mineral-filled materials sandwiched between aluminum sheets, our composite panels offer outstanding fire resistance, weather durability, and design versatility. Available in a wide range of colors and finishes, they bring a sleek, contemporary look to any project while ensuring long-lasting performance.

Our expert team at Vision Art Aluminum provides professional installation services to ensure your project is completed to the highest standards. Whether you’re enhancing a commercial building or improving fire safety, our panels are a trusted solution. With industry-leading warranties, easy maintenance, and quick installation, our composite panels are the top choice for architects and builders.

Aluboard Composite Panel

The Aluboard Composite Panels we provide are premium-quality products, crafted using cutting-edge technology and advanced materials. Every aspect of the design has been thoughtfully engineered and rigorously inspected throughout the production process. These panels distinguish themselves with their versatile applications and numerous advantages.

Aluboard Panels are constructed by bonding polyethylene between two aluminum sheets. The front aluminum surface is coated with durable polyester paint, while the back is finished with epoxy polyester for added resilience. This unique design not only ensures superior protection but also delivers a sleek, modern aesthetic.

Key benefits of these panels include their lightweight construction paired with exceptional strength, as well as a broad range of available colors. Their low-maintenance nature and ease of cleaning further enhance their appeal to users.

The technical specifications of Aluboard Panels are equally impressive. The panels have a thickness of 5 /32 , with widths available in either 50 ” 60 ” The standard length is 126″, with options for lengths up to 236″. The aluminum sheets have a thickness of 0.25 mm.

Thanks to these features, Aluboard Panels are ideal for a wide range of uses, including signboards, advertising displays, and other industrial applications.

Aluface Composite Panel

Our composite panel product, Aluface, is engineered with precision, featuring a front aluminum sheet coated with 0.35 mm of PVDF or Nano PVDF paint for superior protection. The core is reinforced with a 3.30 mm thick low-density polyethylene filler, while the back is finished with a 0.35 mm epoxy polyester-coated aluminum sheet. With an overall thickness of 4 mm, Aluface is recognized for its lightweight design and remarkable durability.

The PVDF coating on Aluface ensures long-lasting resistance to environmental factors while preserving its aesthetic appeal, making it a reliable choice for exterior use. This durability is backed by a 20-year warranty for outdoor applications. Thanks to its premium construction and dependable performance, Aluface has become a go-to solution for architectural projects. We’ve meticulously crafted Aluface to deliver a resilient and trustworthy cladding material for our customers.

| Layers | Thickness | Alloy | Coating |

| Upper Layer Aluminium | 0.35 mm | 3003 H16 | PVDF Coated |

| Core | 3.30 mm | Polyethylene Core | – |

| Lower Layer Aluminium | 0.35 mm | 3003 H16 | Epoxy Polyester Coated |

Saraybond Composite Panel

A2 Class Aluminum Composite Panels are non-combustible and designed for cladding building facades, offering the highest level of fire resistance. With increasing fire incidents worldwide, the need for buildings to be clad with fire- resistant materials has become critical. According to the “Fire Protection of Buildings” regulation (decision number 2009/15316, dated 10.08.2009, by the Council of Ministers), it is mandatory to use A-class non-combustible materials in buildings over 21.5 meters tall.

Our Mineral-Filled A2 Panels feature a total thickness of 4 mm, with 0.5 mm aluminum layers laminated to both sides of a 3 mm non-combustible mineral core. The top aluminum layer is coated with advanced PVDF technology, ensuring maximum durability against harsh weather conditions. Panels produced with this technology come with a 20-year warranty, further enhancing their long-term reliability.

| Layers | Thickness | Alloy | Coating |

| Upper Layer Aluminium | 0.50 mm | 3005 / 3003 H16 | PVDF Coated |

| Core | 3 mm | Mineral Core | – |

| Lower Layer Aluminium | 0.50 mm | 3005 / 3003 H16 | Epoxy Polyester Coated |

ACP Fire Classes

A2 Class Non Combustible (A2 s1 d0) ACP with mineral filled core

B1 Class Fire Retardant (B s1 d0) ACP with FR composed mineral core filled

B2 Class Standard ACP with LDPE core

Coating Technology

All aluminium coils are coated with most advanced coil coating technology. We are able to coat variants of coating types with Textured unlimited color & design option. All the paints used for Aluminum Composite Panels production Is specially developed for our products which provides max protection for all weather conditions. Vision ACP has coating options as below:

Polyvinylidene Fluoride (PVDF)

Antigraffiti PVDF (NANO PVDF )

High Durably Polymer (HDP)

Polyester (PE)

Fluor Polymer (Lumiflon)

Polyurethan Polyamid (PUR/PA)

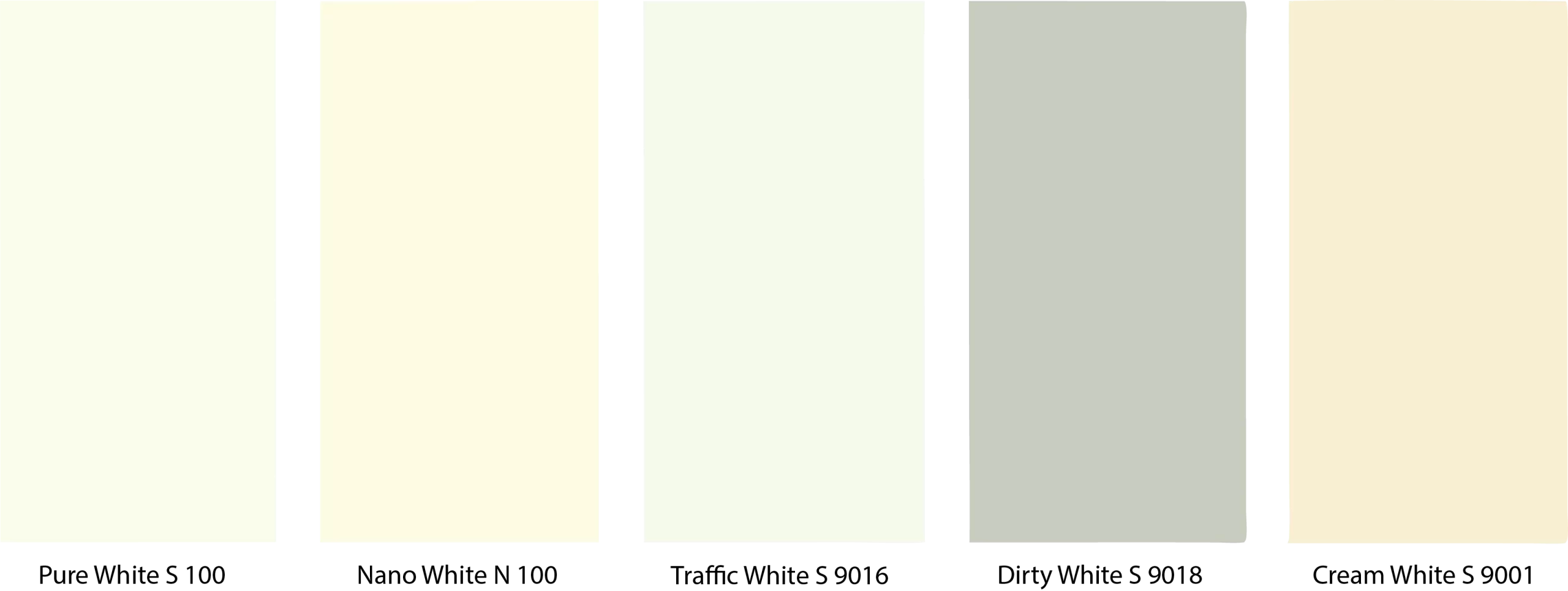

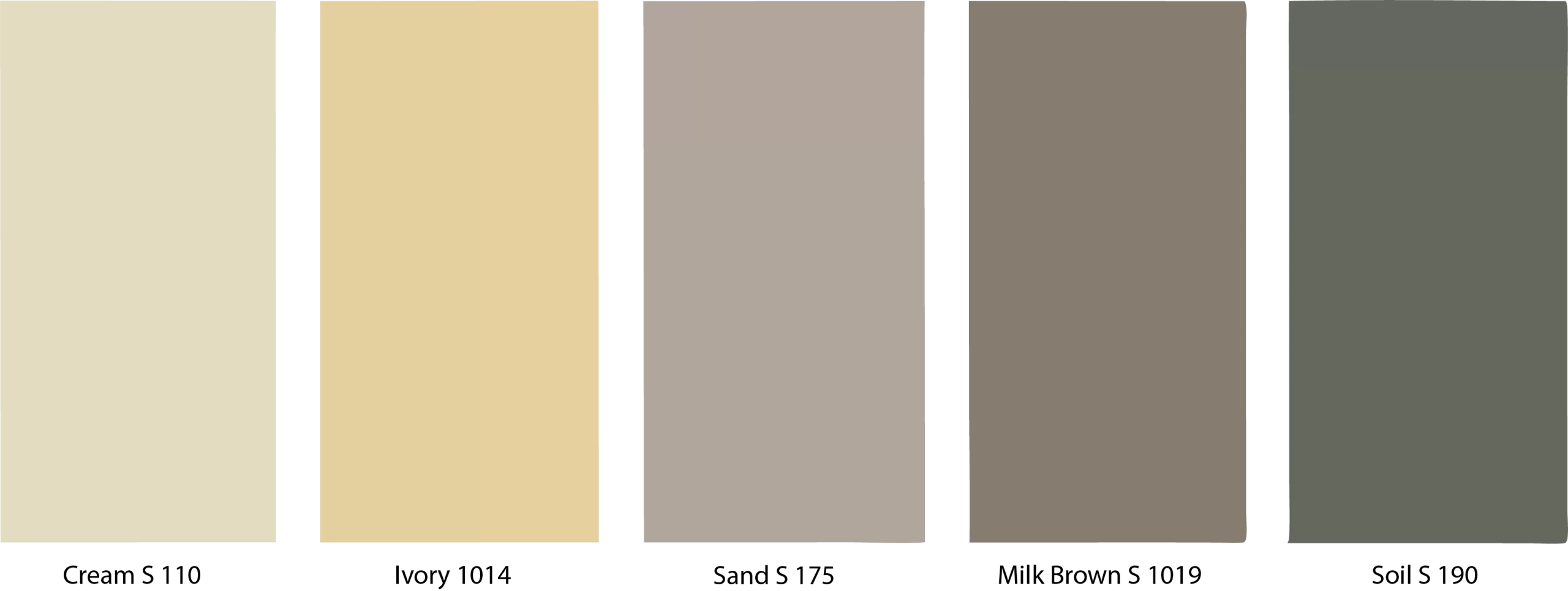

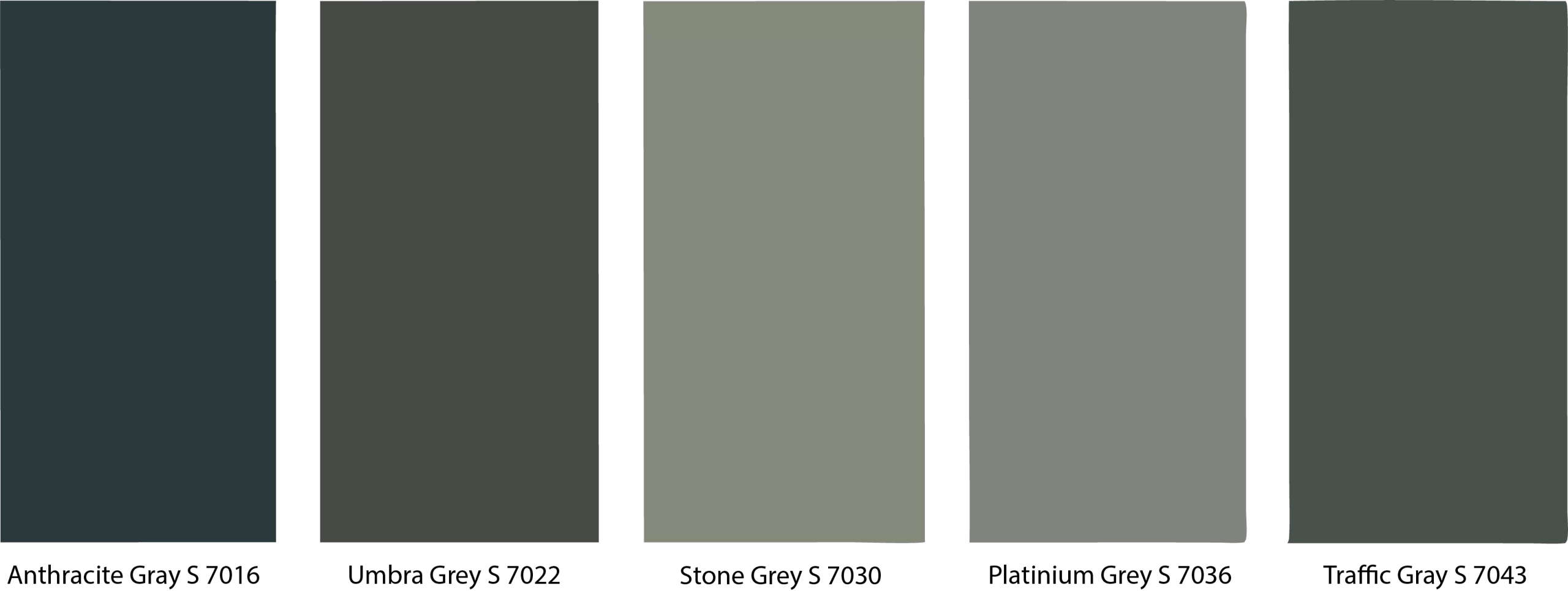

Color Series

We are offering ACP for exterior applications as; Solid Colors, Metallic Finishes, Timber Designs, Stone Effects. Weathered & Zinc & Patina Series, Anodized Outlook, Prismatic Colors, Textured Surfaces and Brushed Surfaces

Environmentally Friendly

Environmental Product Declaration (EPD) is the basis of Sustainability Centifications such as LEED, BREEAM, DGNB and CEDBIK. All SARAY ACP products have International EPD for Green Buildings.

All Vision ACP products have International EPD for Green Buildings.

Warranty

Depending on the coating type and coated layers, SARAY ACP has 10 – 15-20 – 30 or 40 years warranty for exterior cladding.

Just Desire…

Desired Colors & Designs

In addition to the 70+ options in our color chart, we can coat any desired color & design

Desired Opaqueness

If you choose a matte outlook in your project we can coat Ultra Matt; 0-5 % gloss

Desired Brightness

If you choose an brillant outlook in your project we can coat High Gloss; 90-95 % gloss

Solid Colors, Colors Your World With Unlimited Options

Shades of Grey

Aluminum Composite Panel Technical Data

STORING

Panels must be stored In a cool, dry area. We recommend to store the panels In the workshop at approximately 18 °C for at least 24 hours before processing operations begin.

Store the pallets stacked one over the other (do not store panels standing vertically) with a maximum of 5 pallets of the same format stacked on top of each other (heavy pallets at the bottom).

Individual panels must be lifted off the pallet by two people holding all four corners and not drawn over each other. Carry the panels vertically.

Wear gloves to avoid staining.

When stacking panels, nothing should be put in between to avoid markings.

CONTROLLING

Check finishing colour by stripping the comer of the panels before processing.

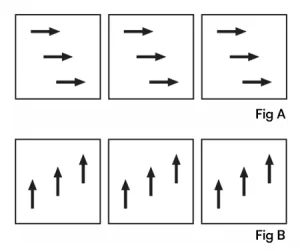

MATCHING (INSTALLATION ) PANELS WITH METALLIC & MICA COATINGS

Arrows showing the direction of coil coating are printed on the strippable protective film. Panel directionality must be maintained in order to avoid shading differences between adjacent panels and must be taken into account when making the optimisation calculations. Be sure all panels must be installed in the same direction as seen in Fig A and Fig B below You must NOT mix directions A and B. Otherwise different shades become visible.

Request a Quote

For Business: Do you have questions about how Manufactory can help your company? Send us an email and we’ll get in touch shortly, or phone +1 646 270 8983 between 09:00 and 17:00 Monday to Saturday — we would be delighted to speak.

Note: Your details are kept strictly confidential as per our Company Privacy Policy.