Aluminium Composite Panel (ACP) is a versatile and durable material widely used in building construction, signage, and other applications where strong yet lightweight materials are required. These panels consist of two thin layers of aluminium enclosing a non-aluminium core, which provides added strength and rigidity. Over the years, ACP has become a popular choice in various industries due to its modern aesthetic, excellent mechanical properties, and cost-efficiency.

Aluminium Composite Panels have revolutionized the construction and design industries by offering a perfect balance between aesthetics, durability, and cost-efficiency. From cladding and interior design to signage and transportation, ACPs are highly versatile, making them a preferred material across various applications. By understanding their composition, advantages, and proper maintenance, users can maximize the benefits of ACP in their projects.

This article explores everything you need to know about Aluminium Composite Panels, including their composition, features, uses, advantages, and maintenance.

Understanding Aluminium Composite Panel (ACP)

Aluminium Composite Panel (ACP) is a sandwich structure comprising two aluminium sheets and a core made from non-aluminium material, often polyethylene (PE) or a mineral-filled core to enhance fire resistance. The combination of materials gives ACPs a sleek appearance and a balance of strength and flexibility, making them suitable for a range of construction and design purposes.

The typical thickness of ACP ranges from 3mm to 6mm, though various thicknesses can be custom-ordered depending on the application. The aluminium layers are usually pre-treated to resist corrosion and enhance adhesion, ensuring durability and longevity.

Components of Aluminium Composite Panels

An ACP panel consists of the following components:

a) Aluminium Sheets

The aluminium sheets used in ACP are generally 0.5 mm thick and form the outer layers of the panel. These sheets are often coated with protective finishes such as PVDF (Polyvinylidene fluoride) or polyester to resist weathering, corrosion, and UV radiation.

b) Core Material

The core of ACP plays a critical role in its strength and fire-resistance properties. Two types of core materials are commonly used:

- Polyethylene (PE) Core: A low-density plastic that makes the panel lightweight but combustible. ACPs with PE cores are often used in non-fire-critical applications such as interior cladding and signage.

- Fire-Resistant (FR) Core: Made from a mineral-filled core, FR ACPs are designed to comply with fire safety standards. They are recommended for exterior cladding in high-rise buildings and public spaces.

c) Adhesive Layer

The core and the aluminium sheets are bonded together with high-performance adhesive layers, ensuring structural integrity and preventing delamination, even under harsh environmental conditions.

Key Features of Aluminium Composite Panels

Several factors make ACP an attractive choice in construction and design industries:

a) Lightweight and Flexible : Despite their robust structure, ACPs are relatively lightweight, making them easy to transport and install. Their flexibility allows them to be curved or folded, catering to various architectural designs.

b) Aesthetic Versatility : Aluminium Composite Panels offer a wide variety of finishes, including metallic, mirror, wood, and stone textures. These finishes can replicate traditional materials while offering the benefits of modern technology.

c) Durable and Weather-Resistant : The aluminium layers in ACP are coated with protective finishes that resist corrosion, UV radiation, and moisture. This durability makes them suitable for outdoor applications where they are exposed to changing weather conditions.

d) Fire-Resistant Options : Fire-rated ACPs with mineral-filled cores meet international fire safety regulations, making them safe for use in high-rise buildings, airports, hospitals, and other sensitive environments.

e) Sound and Thermal Insulation : The core material in ACPs provides thermal insulation and soundproofing properties, helping improve energy efficiency and noise control in buildings.

Applications of Aluminium Composite Panels

Aluminium Composite Panels have a broad range of applications, owing to their adaptability, cost-effectiveness, and superior properties. Some of the most common uses include:

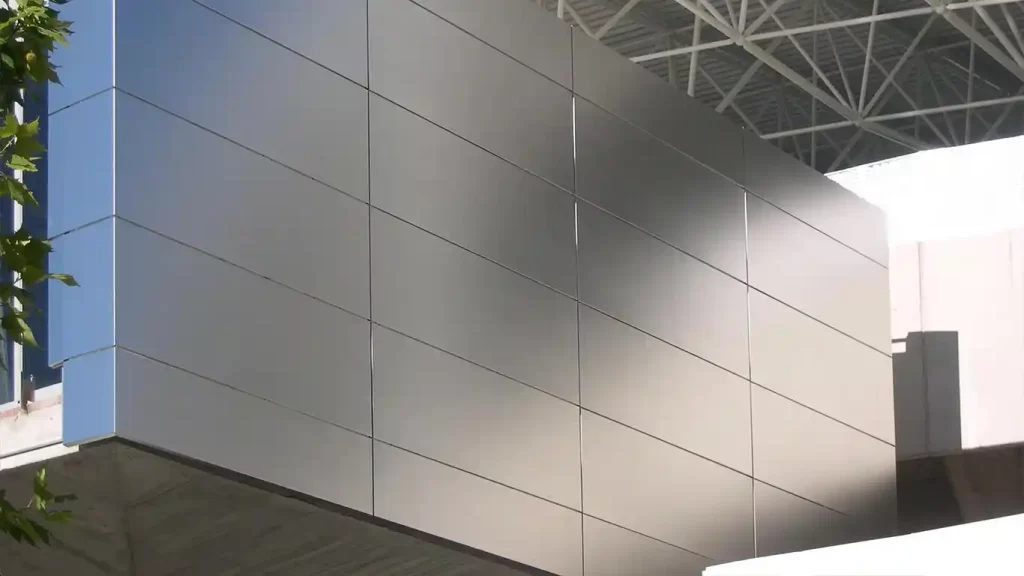

a) Exterior Cladding : One of the most prominent applications of ACP is in the construction of facades and exterior walls. Architects and builders prefer ACP for its modern look, durability, and the ability to be customized in various colors and textures.

b) Interior Design : ACP is widely used in interior spaces such as walls, ceilings, partitions, and false ceilings. Its aesthetic appeal and easy installation make it a popular choice for modern interiors, especially in commercial and residential buildings.

c) Signage and Advertising : Aluminium Composite Panels are frequently used in the production of outdoor signage, billboards, and display boards. Their weather resistance and lightweight properties make them ideal for long-term outdoor use.

d) Transportation : ACP is used in vehicle bodies, especially for buses, trucks, and trailers, due to its lightweight nature and the ability to withstand exposure to the elements.

e) Furniture : ACP is occasionally used in the manufacturing of lightweight yet durable furniture, particularly in modern and minimalist designs where clean lines and sleek finishes are desired.

Advantages of Using Aluminium Composite Panels

The widespread use of Aluminium Composite Panels in construction and other industries is due to the numerous advantages they offer:

a) Lightweight Construction : ACP’s lightweight properties make it easier to handle, transport, and install compared to heavier materials like concrete or solid metal sheets. This reduces labor costs and installation time.

b) Cost-Efficiency : Aluminium Composite Panels are generally more affordable than traditional materials such as solid aluminium or steel, making them an attractive option for budget-conscious projects. Their longevity and low maintenance requirements further enhance cost savings.

c) Aesthetic Appeal : With a wide range of finishes and colors, ACP offers immense creative possibilities for architects and designers. Whether it’s replicating natural textures or creating a bold modern look, ACP can be tailored to fit various design requirements.

d) Durability and Low Maintenance : ACP panels are known for their resistance to corrosion, weather damage, and pollution. The protective coating on the aluminium layers ensures that the panels retain their aesthetic appeal with minimal maintenance.

e) Eco-Friendly : Many ACP manufacturers use recycled aluminium, and the panels themselves are recyclable, contributing to sustainable construction practices.

f) Fire Safety (FR Panels) : Fire-resistant ACPs meet stringent fire safety standards, providing peace of mind in applications where fire safety is a priority, such as in high-rise buildings.

Maintenance of Aluminium Composite Panels

One of the advantages of ACP is its low maintenance requirement. However, regular cleaning and inspection are essential to ensure longevity and performance.

a) Cleaning : For exterior applications, ACP surfaces should be cleaned periodically to remove dirt, grime, and pollutants. Use mild detergents and soft cloths to avoid scratching the surface.

b) Inspections : Regular inspections should be conducted to check for any signs of delamination, corrosion, or surface damage, especially after extreme weather events.

c) Repair : Minor damages such as scratches or dents can be repaired using touch-up paint or panel replacement, depending on the severity of the damage.

FAQ in Aluminium Composite Panels

What is the difference between PE core and FR core ACP?

PE core ACPs have a polyethylene core, which is lightweight but flammable. FR core ACPs have a mineral-filled core, providing enhanced fire resistance.

Can Aluminium Composite Panels be recycled?

Yes, ACPs are recyclable, and many manufacturers use recycled aluminium in the production process, making them an eco-friendly option.

What is the standard thickness of ACP?

The typical thickness of ACP ranges from 3mm to 6mm, though custom thicknesses can be produced depending on the application.

How long does Aluminium Composite Panel last?

With proper maintenance, ACPs can last anywhere from 20 to 30 years, depending on environmental conditions and usage.

Is ACP suitable for high-rise buildings?

Yes, especially fire-resistant ACPs, which meet the necessary fire safety regulations, making them ideal for cladding high-rise buildings.

How should ACP be cleaned and maintained?

ACP should be cleaned periodically with mild detergent and soft cloths to remove dirt and pollutants. Regular inspections are also recommended to check for signs of wear.